Welcome to the MCENTER MACEDONIA,

MIS brand new Digital Dentistry Department

This high-tech facility is home to our Guided lmplantology System – MGUIDE, as well as our CAD/CAM Laboratory – edentallab. Our full digital solution allows clinicians to not only place implants with guided precision, but also restore those implants with customized components. We are proud to offer these services to our clients in accordance with the value to which they are all accustomed.

MSOFT is an advanced virtual implant planning software system that has been developed by MIS to accurately transform DICOM data into 2D and 3D images that depict real cases in a virtual environment; enabling real-time 2D and 3D visualization for perfect implant planning.

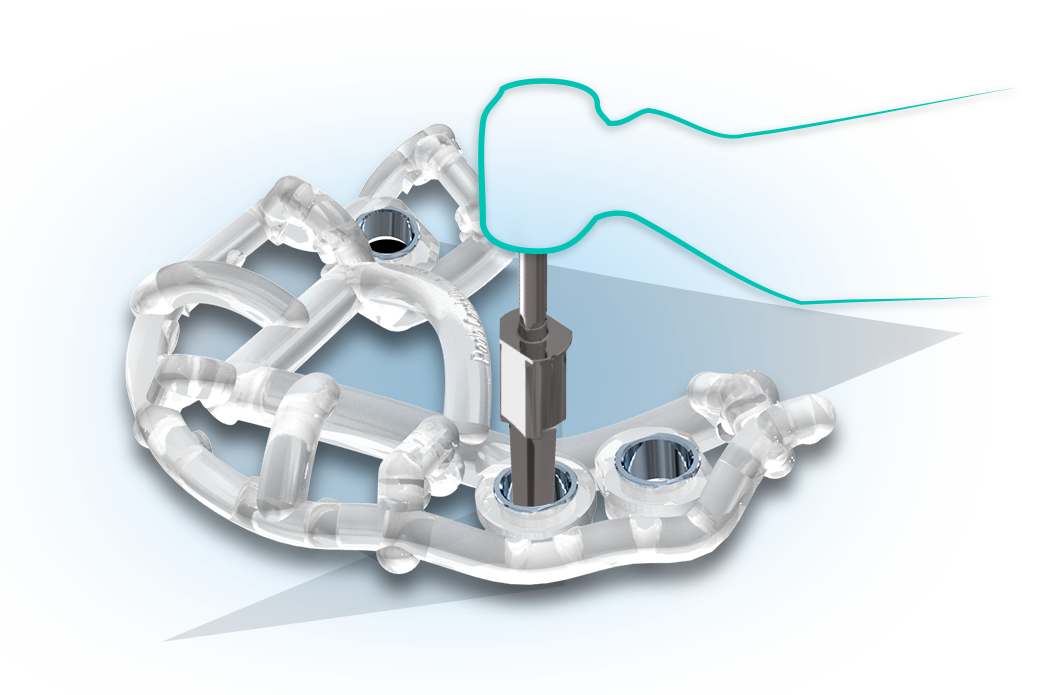

The MGUIDE system delivers optimized guided surgery templates, for a more accurate surgical procedure and predictable prosthetic outcomes. The open wire-frame template allows seating fully braced in the patient’s mouth. The system further allows easy access for irrigation and anesthesia, plus flexibility in performing the surgical procedure from an anatomical standpoint, including implant replacement as needed, without changing or redesigning the template.

CAD/CAM, Computer-Aided Design and Computer-Aided Manufacturing in dentistry, utilizes digital technology to provide a range of highly accurate dental restorations. The MLAB system includes a 3D scanner, advanced design software, and a milling machine (manufacturing process).

MSOFT is an advanced virtual implant planning software system that has been developed by MIS to accurately transform DICOM data into 2D and 3D images that depict real cases in a virtual environment; enabling real-time 2D and 3D visualization for perfect implant planning.

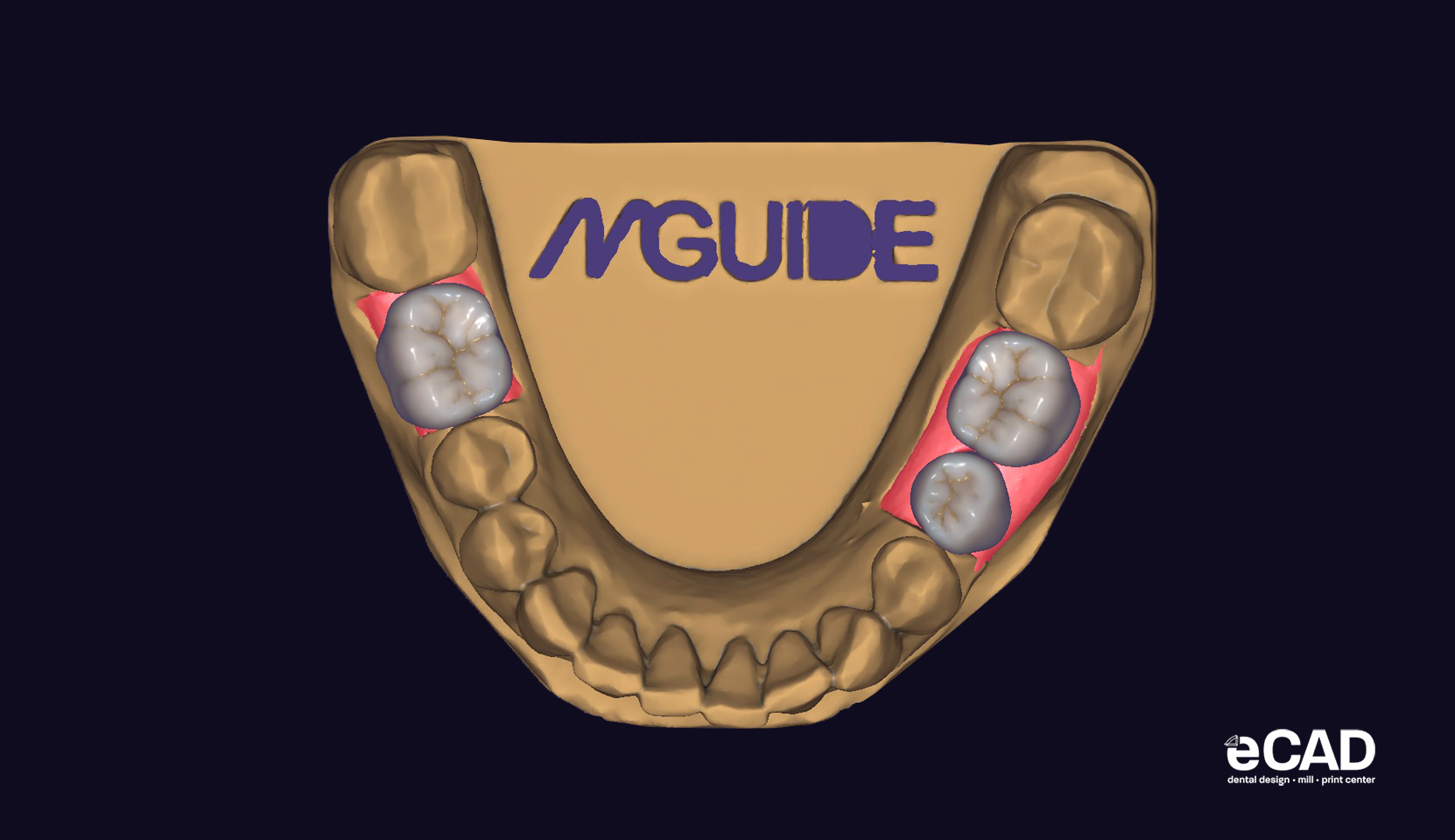

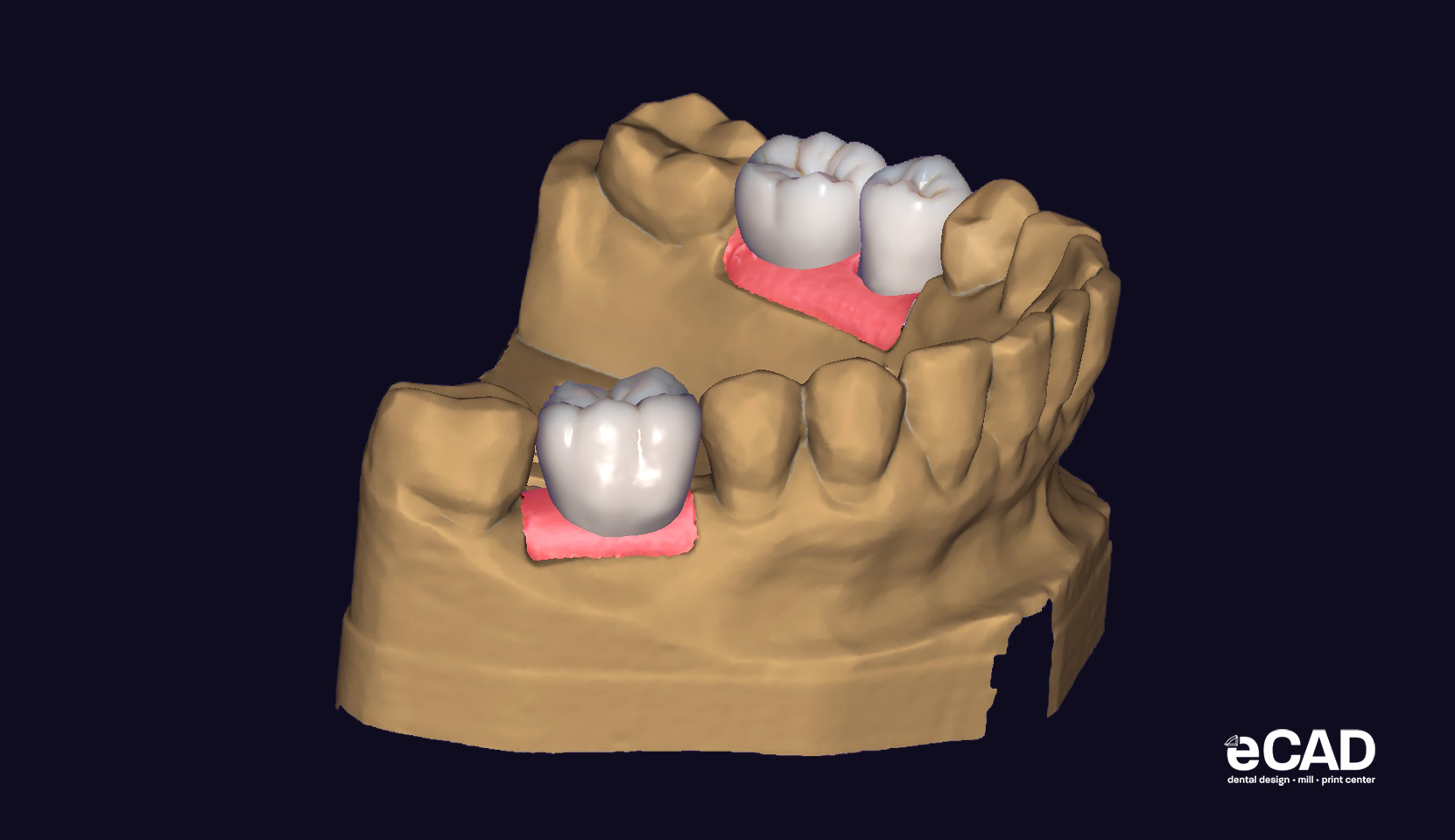

Virtual Planning Process

The MSOFT program creates a highly accurate preliminary implant placement plan, taking all aspects of the patient anatomy into consideration. A precision-guided surgical template is then designed right in the software. Flexible prosthetic-driven planning can be done either by the clinician, using our simplified MSOFT program, or through our worldwide network of MCENTERs, providing technical support and guidance.

Diagnostics

The open-frame design of the MGUIDE template allows an open field of view during surgery, where irrigation and anesthesia are accessible from all angles without removing the template. With a fully customized MGUIDE design, a raised-flap procedure may be performed. The template is constructed from a strong, durable and biocompatible material. The 3D CAD/CAM design ensures the highest level of accuracy. The lightweight template design is an added benefit for patient comfort as well.

Implant Positioning

The MSOFT program generates multi-level, 2D planning views and 3D composite representations of the patient’s anatomy, in order to create the perfect placement and surgical plan. This same high precision technology is used to print the open-frame drilling template that allows quicker, more accurate implant placement for the benefit of the dentist and patient alike.

Patient Communication

When a surgeon or dentist can refer to measurable values rather than subjective judgments alone as the basis for decision-making, it is easier to explain treatment choices to patients.

The MGUIDE system delivers optimized guided surgery templates, for a more accurate surgical procedure and predictable prosthetic outcomes. The open wire-frame template allows seating fully braced in the patient’s mouth. The system further allows easy access for irrigation and anesthesia, plus flexibility in performing the surgical procedure from an anatomical standpoint, including implant replacement as needed, without changing or redesigning the template.

Brand

MIS MGUIDE – Full Smile Solution

From planning to 3D modeling and uniquely designed and patient specific surgical templates, and on through same day provisional restoration, MIS is truely offering the patient a Full Smile Solution with its “one-stop-shop” for digitally guided surgery.

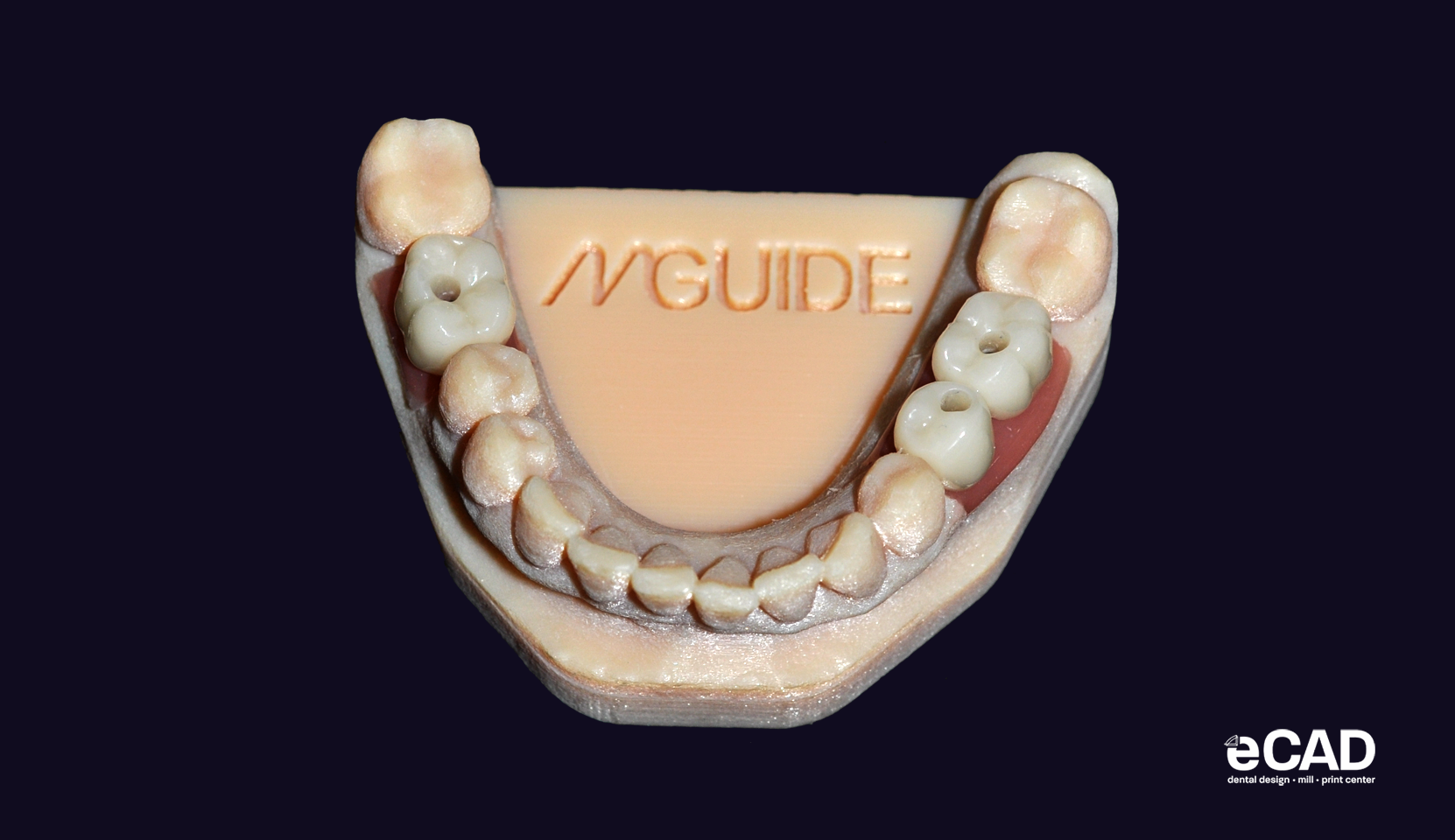

MGUIDE Template

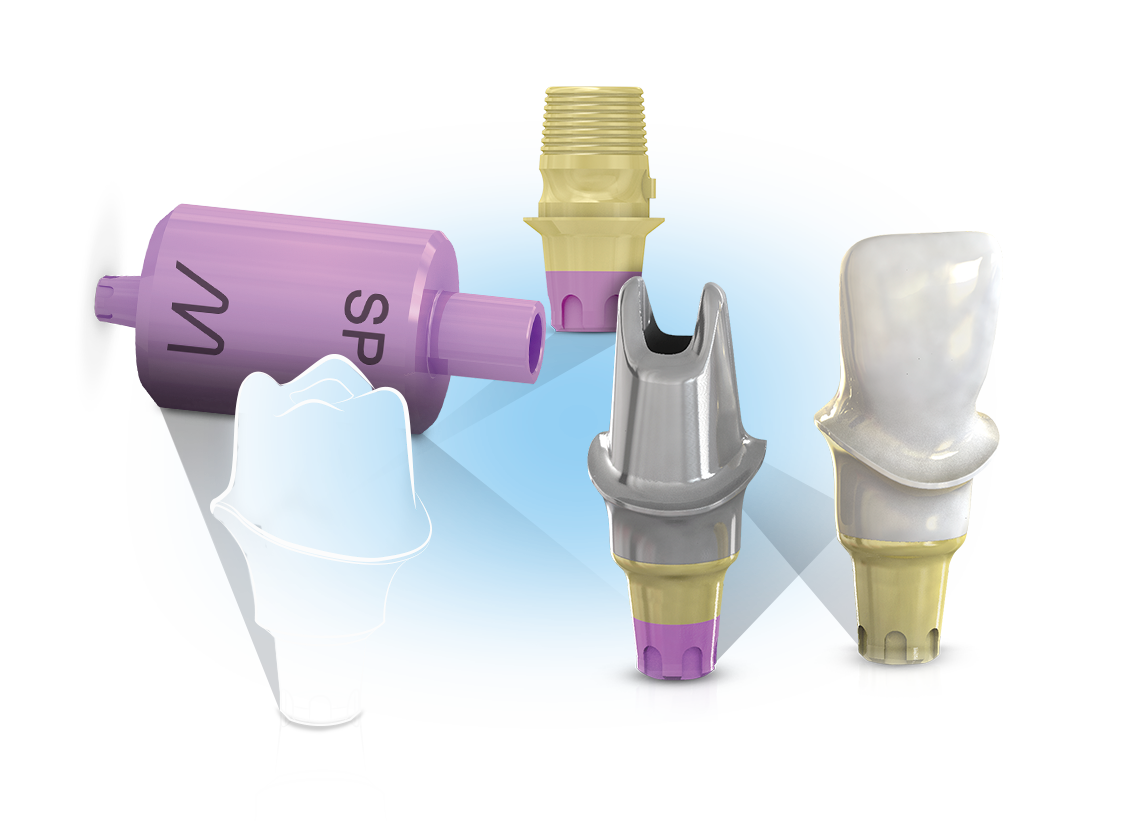

Using MSOFT, the clinician is able to see through bone to detect structures or flaws, which may impact drilling and implant placement. Implants may be more accurately placed according to depth, position and angulation in relation to the desired prosthetic solution. The software enables the clinician to determine the most suitable abutment type according to gingival and prosthetic heights, as well as angulation of the abutment.

Implant Positioning

MGUIDE surgical kits simplify the implantology process by eliminating the need for traditional guidance keys.

Specially designed sleeves and drills stop at the precisely planned position and depth, freeing-up hands and saving valuable time.

MIS has a comprehensive set of surgical kits which include:

Conical Connection Surgical Set for V3 and C1 implants procedure

Internal Hex. Surgical Set for SEVEN implant procedure

Narrow Sleeve Kits – for both conical and internal hex. connections, ideal for implant placement in mandibular anterior regions, between teeth and where standard sleeves are too large

Universal Pilot Drills Kit – suitable for all MIS implants models, and used for first stage implantation procedures

Technology Taken to the Limits – Make it Simple

Pushing the envelope of today’s technological advancements means MIS continuously explores new ways in which technology can take implant dentistry to the next level for optimal results.

CAD/CAM Technology

MCENTER MACEDONIA with an in-house laboratory can provide immediate temporary custom healing caps, abutments and screw-retained crowns and bridges from PMMA. Additionally, permanent custom abutments and copings are available in Zirconia and Titanium.

Scan Posts

The MIS Scan Posts, with patent-pending design features, offer excellent surface quality, allowing easy scanning and unique geometry. Well-defined flat surfaces for easy placement and optimum accuracy. No spraying or pre-scanning needed. Suitable for both Intra Oral and desktop scanning.

Digital Model Analogs

The Digital Analog for a printed model is used in a fully digital procedure using intra-oral scanning, including virtual implant planning, placement and digital restoration printing. Designed with geometry which provides optimal precision, the analog ensures exact positioning in a 3D printed model. That leads to accurate restoration planning and simulation.